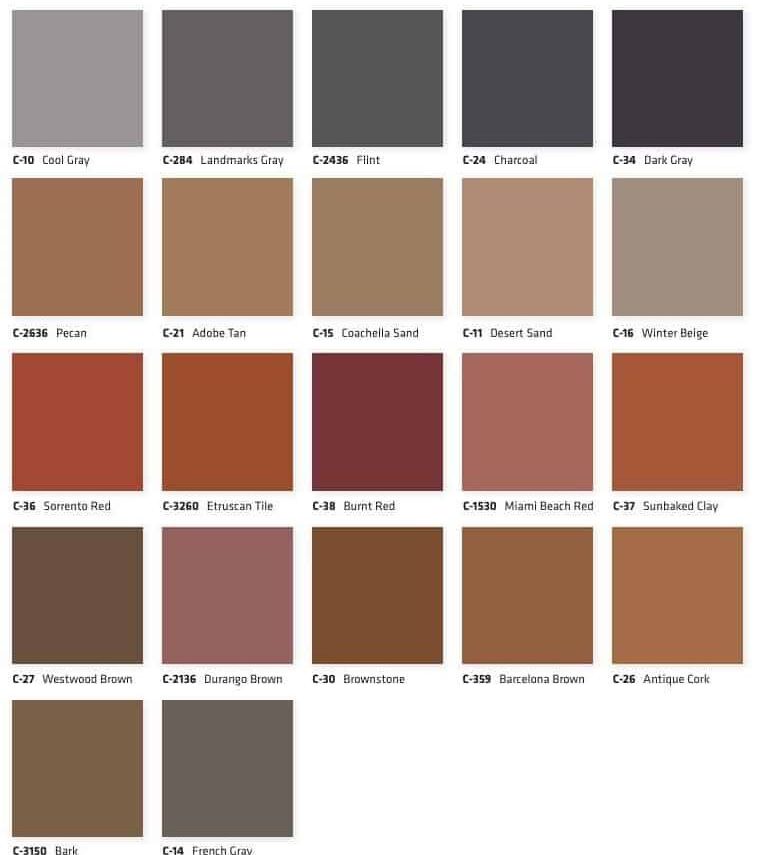

Color Center

We can meet and match any color at a portion of the price with our

at home color selection saving our client in cost and time while

maintaining the desired quality and color depth.

Click below to learn how Tec-Crete can help you meet

the concrete color tether to your needs.

the concrete color tether to your needs.

SIKA FIBER

Sika's high performing polymer fibers offers the performance of steel fibers at lower dosage rates and cost. The unique anchorage system of each synthetic fiber and the higher aspect ratio (length/diameter) allows for higher performance in the concrete matrix. The synthetic fibers infuse the concrete with added levels of toughness, energy absorption and durability. In addition, synthetic fibers provide an added measure of crack control without the risk of corrosion associated with steel.

Low Cost, reliable and safer for the enviroment

Micro Fiber

SikaFiber® PPM 150

Superior to wire mesh and does not corrode

Macro Fiber

SikaFiber® Force 650

SIKA ADMIXTURES

Hydration Control

Specific jobs requirements regarding extended workability time of concrete before hardening can be perfectly tailored with the help of retarders.

SikaTard®440

Water Reducer & Enhancer

Used in ready mix applications, as a plant added high range water reducer to provide excellent plasticity while maintaining slump, admixtures enable water reduction and workability retention.

Sika®ViscoCrete2100

Sikament®475

Viscosity Modifier

Sika's admixtures enables concrete to flow easily through and into confined spaces.

Sika® Stabilizer-4R

Accelerating & Anti Freeze

All participants in the construction process want to achieve sufficient early strength to allow formwork removal as quickly as possible.

Plastocrete® 161FL

SikaRapid®1

Waterproofing & Resistence

Sika® Watertight Concrete Powder is a combined water resisting and HRWR/Superplasticizing admixture used to enhance the workability and reduce the water permeability of concrete.

Sika WT-240p

Sika WTP

Shrinkage Control

Sika® Watertight Concrete Powder is a combined water resisting and HRWR/Superplasticizing admixture used to enhance the workability and reduce the water permeability of concrete.

SikaControl®75

Corrosion Inhibitor

Sika® CNI is a calcium nitrite-based admixture designed to inhibit the corrosion of steel in reinforced concrete. Sika® CNI contains a minimum of 30% calcium nitrite by mass and meets the requirements of ASTM C1582

Sika®CNI

Finishing Aid & Evaporation Control

Sika® Film is recommended for use in all applications where a superior finish is required on concrete flatwork. Sika® Film protects concrete from the effects of excessive moisture loss in rapid drying conditions.

Sika®FILM

CEMENTITIOUS

Type I/II Cement

Cement acts as the binding agent or glue in concrete. When combined with water, cement forms a paste that coats the sand and gravel. Through a chemical reaction called hydration, the mixture sets and hardens into concrete.

When freshly mixed, concrete can take any shape or form; when hardened, it’s strong and durable. These qualities explain why one material, concrete, can build everything from skyscrapers and sidewalks to highways and dams.

Slag cement, a byproduct of steel-making, enhances the traditional concrete benefits of strength and durability while offering reductions in waste, energy use and greenhouse gas emissions.

Slag cement is used in concrete for virtually any construction application, either in conjunction with traditional portland cement, part of blended cement or as a separate component. It typically replaces part of the portland cement in concrete mixes.

Grade 120 Slag

Fly ash

Fly ash is a byproduct of coal combustion in electric power plants. It’s the very fine ash recovered from exhaust gases by emission-control systems. Fly ash is a pozzolan, virtually identical to volcanic ash.

When used in concrete mixes, fly ash is known as a supplementary cementing material, or SCM. Fly ash is the most widely used SCM, and has been added to concrete since the 1930s. It can supplement cement on its own or used in conjunction with other SCM in blended cements.

NYSDOT State Sand

NYSDOT Dolomite Stone

(Normal Weight)

NYSDOT Trap Rock

(Friction-Normal Weight)

NYSDOT Light Weight Stone

Manufacturing, supplying and distributing

quality aggregates.

Ready Mix Concrete products delivered to

you with unparalleled service.

Concrete that is strong and durable for

many years to come.